Transformer is the key equipment in the power system, and its normal operation is an important guarantee for the safe, reliable, stable and economical operation of the power system. When the power transformer is running, there is an alternating magnetic field around the winding. Due to the effect of electromagnetic induction, there are parasitic capacitances between the high-voltage winding and the low-voltage winding, between the low-voltage winding and the iron core, and between the iron core and the shell, the live winding will, through the coupling of parasitic capacitors, cause the iron core to produce a suspended potential to the ground. Because the distance between the iron core and other metal components and the winding is not equal, there is a potential difference between the components. when the potential difference between two points to the breakdown of the insulation, spark intermittent discharge will occur, which will adversely affect the transformer oil and solid insulation. Therefore, it is necessary to connect the iron core to the shell to make it equipotential with the shell. If the iron core or other metal components are grounded at two or more points, the grounding point will form a closed loop, resulting in a circulating current, which will cause local overheating of the transformer body, resulting in oil decomposition, and then lead to a decrease in insulation performance. In severe cases, it will cause iron core silicon steel chip burns out, causing a major accident of the main transformer, so the iron core of the main transformer must be grounded. Otherwise, the iron core will generate a floating voltage to the ground or the iron core will be grounded at multiple points, resulting in a heating fault, which will seriously threaten the safety of the transformer and the power grid. By monitoring the grounding current of the iron core, faults such as multi-point grounding of the iron core can be found in time, preventing problems before they occur, and eliminating the faults in the bud.

TRKXL-60W transformer core grounding sensor is a special supporting client "transformer core and clip grounding current monitoring device", which is used to monitor the ground fault current of transformer core and clips, and can realize continuous and online monitoring of core grounding current. Through monitoring, the insulation status of the equipment can be monitored in real time, and faults such as damp or damaged internal insulation, multi-point grounding of the iron core, foreign objects in the box, and sludge deposition in the fuel tank can be found in time. More importantly, it can provide reliable data basis for the condition maintenance of such equipment.

The material with high initial permeability is selected as the iron core, and the unique deep negative feedback technology and multi-layer metal shielding measures are adopted, which can fully automatically compensate the iron core and make the iron core work in an ideal zero magnetic flux state. The sensor can accurately detect the power frequency current of 100μA-700mA. The phase transformation error is not greater than 0.01°, and it has good temperature characteristics and electromagnetic field interference ability, which fully meets the accuracy of equipment sampling under complex power station field interference.

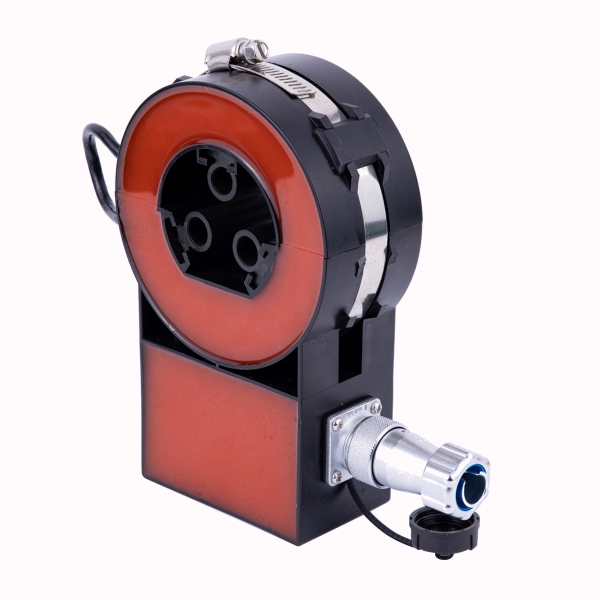

Open and close structure, easy to install on site and easy to operate. Quick and easy installation or removal without disconnecting the primary cable under test;

It can accurately measure μA-level current, with high measurement accuracy and good linearity;

Multiple shielding, strong anti-interference ability, can work in complex environment;

Optional shielded wire or aviation plug output;

Special waterproof and anti-corrosion metal shell, epoxy resin potting, can work outdoors for a long time.

On-line monitoring of transformer core grounding; on-line monitoring of high-voltage bushing insulation; on-line monitoring of zinc oxide arrester insulation; on-line monitoring of current, voltage transformers and capacitors; high-voltage live display.

Electric

Performance

Parameters |

Electrical Symbol |

Performance |

Opened and Closed Lock Type |

| I P |

Measurable Range |

0.1mA~1A |

| VOUT |

Rated Output |

0~7Vrms |

| X |

Accuracy @IPN |

0.3% |

| εL |

Linearity |

≤0.1% |

| Uc |

Supply Voltage |

±12V |

| VOff |

Offset Voltage |

1mV |

| IC |

Max Power Consumption |

10mA |

| f |

Operating Frequency |

50~400 Hz |

| TA |

Operating Temperature |

-40℃~+85℃ |

| TS |

Storage Temperature |

-40℃~+100℃ |

Mechanical

Structure

Parameters |

Shell |

Metal Shell |

Output Method |

Shielded cable/waterproof aerial plug |

| Metal Core Material |

Nanocrystalline/Permalloy |

Seal |

Flexible silicone & Epoxy |

| Magnetic Screen Structure |

Carbon steel/Permalloy |

Construction Plan |

Base installation fixed |

Shape and Installation Dimensions